Come and visit

our sample room

& factory

Come and visit our sample room for some inspirational

ideas on your kitchen or bathroom!

Specifically designed to meet the requirements of padel, the recyclable artificial turf boasts optimal functional properties that allow athletes to perform at their peak.

Assess slope and topography for drainage glow.

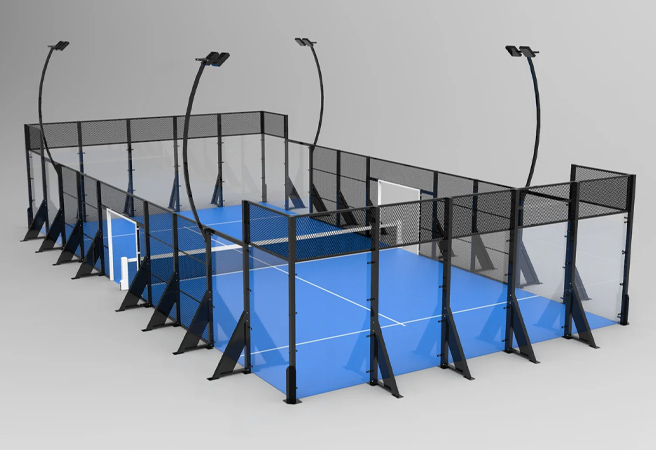

This structure provides larger anchors and serves as the foundation for fencing and walls, as the client frame is steel and will require more load bearing.

300mm wide x 500mm deep

4 longitudinal rebars + stirrups @ 200mm c/c

C25/30 minimum

150mm

Welded mesh or steel bars

Power floated or brushed to provide grip

Type E1 Lakfold padel base to reduce impact and improve energy absorption

Professional turf performance installed over sub surface.

Pillar and popup style padel tennis courts, 10mm toughened (tempered) glass is commonly used as the rear and side enclosures. Below are the technical specifications, standards, and installation considerations for this type of glass in padel court applications.

Back Wall Panels:

Glass thickness:

Large panels with minimal framing require greater thickness (12 mm) for stability and wind resistance.

Side Wall Panels:

Side Wall Panels:

Type:

Impact Resistance:

Breakage Mode:

Complies with:

Edges:

Spacer Gaskets:

Drillings:

No vertical pillars in the corners—glass panels are joined with special connectors or adhesives, and supported by:

Mounting:

Must withstand:

Wind Load Tests:

Can include:

12 mm toughened glass offers some noise containment but does not

absorb sound like acoustic glazing. It reflects noise effectively.

| Panel Size | Thickness | Weight (Approx.) |

|---|---|---|

| 3000 × 2000 mm | 12 mm | ~180 kg |

| 2000 × 2000 mm | 12 mm | ~120 kg |

Panels are delivered in steel A-frame stillages, often with vacuum lift needed for on-site handling.

| Feature | Value |

|---|---|

| Glass Thickness | 12mm |

| Panel Sizes | Up to 3000 x 2000 mm |

| Standards | EN 12150-1, FIP compliant |

| Mounting Style | Frameless/minimally framed |

| Installation | Base channel + bracket + corner join |

| Edge Finish | Polished (safe to touch) |

| Typical Use | Premium/viewer-facing courts |

Here's a full breakdown for 12 mm toughened glass, the industry standard for panoramic padel courts:

Back Wall Panels:

Side Wall Panels:

Large panels with minimal framing require greater thickness (12 mm) for stability and wind resistance.

Complies with:

Drillings:

No vertical pillars in the corners—glass panels are joined with special connectors or adhesives, and supported by:

Mounting: Fixings from the base or occasionally top-framed with stabilising bars

Must withstand:

Wind Load Tests: Usually rated for up to 0.8–1.0 kN/m² depending on fixings and installation height

Can include:

12 mm toughened glass offers some noise containment but does not absorb sound like acoustic glazing. It reflects noise effectively.

| Panel Size | Thickness | Weight (Approx.) | Glass Type |

| 3000 × 2000 mm | 12 mm | ~180 kg | Toughened |

| 2000 × 2000 mm | 12 mm | ~120 kg | Toughened |

Panels are delivered in steel A-frame stillages, often with vacuum lift needed for on-site handling.

| Feature | Value |

| Glass Thickness | 12 mm |

| Panel Sizes | Up to 3000 x 2000 mm |

| Standards | EN 12150-1, FIP compliant |

| Mounting Style | Frameless/minimally framed |

| Installation | Base channel + bracket + corner join |

| Edge Finish | Polished (safe to touch) |

| Typical Use | Premium/viewer-facing courts |

We are finalising design of canopies - watch this space

Full Turnkey Supply & Installation (Phase 1-4).

Elements can supply complete padel court solutions, including optional add-ons and services.

With a presence in over 120 locations around the globe, SYNLawn serves as your trusted partner for top-quality and sustainable artificial grass solutions. As a distributor, we work seamlessly, promoting responsible environmental stewardship through industry-leading innovations in artificial grass solutions. SYNLawn continues to lead the industry by continuously raising the bar for global synthetic turf standards.

All other materials are environmentally sourced including the glass which is Low-Carbon glass.

Come and visit our sample room for some inspirational

ideas on your kitchen or bathroom!